Product Description

Product Description

CHINAMFG IS A PROFESSIONAL MANUFACTURE OF TOWER CRANE

ELMAK PRODUCTS LIST:

Hammer head cranes

Flat top cranes

Luffing tower cranes

Passenger hoist

Suspended platform

Spare parts

CHINAMFG Crane Spare Parts

ELMAK CRANE Spare Parts

ELMAK CRANE (ZheJiang ) CO., LTD offers a comprehensive ONE-STOP tower crane spare parts center. We provide spare parts for all major crane brands, excluding CHINAMFG crane itself. Our extensive inventory ensures that you can find the parts you need quickly and efficiently.

Features:

- ONE-STOP tower crane spare parts center

- Supplies spare parts for all major crane brands

- Extensive inventory for quick access to needed parts

Product Parameters

ELMAK CRANE (ZheJiang ) CO., LTD Spare Parts

Our spare parts inventory includes a wide range of essential components for cranes such as fixing angles, mast sections, pins, ladders, slewing rings, motors, gearboxes, pinions, limit switches, winches, wire ropes, electrical cables, contactors, pulleys, rollers, RCV, VAC, OMD, HRCV, brushes, and more.

Ensure the smooth operation and maintenance of your crane with our high-quality spare parts designed for durability and reliability.

| ELMAK TOWER CRANE SPARE PARTS | |||||||

| No. | Performance Parameter | Output gear | Weight | RCVseries | JHFseries | Recommended for tower cranes | |

| Torque motor | Inverter motor | ||||||

| Transmission ratio | Output torque | (kg) | Motor rated stall torque | Motor Power | |||

| (N·m) | (N.m) | (kW) | (t·m) | ||||

| JH07 | 176 | 6000 | m=10,z=12,x=+0.32 | 90 | 75,95 | 4.4,5.5 | 40~125 |

| JH08 | 164 | ||||||

| JH13 | 143 | 9000 | m=10,z=13,x=+0.5 | 130 | 95,120 | 5.5 | 63~160 |

| JH13C | 162 | ||||||

| JH02 | 163 | 12000 | m=12,z=12,x=+0.5 | 150 | 145,185 | 9 | 160~250 |

| JH02C | 192 | ||||||

| JH17 | 200 | 18000 | m=16,z=12,x=+0.5 | 240 | 11,15 | 315~630 | |

| JH15 | 160 | 24000 | m=18,z=14,x=+0.5 | 410 | 11,15 | 450~900 | |

| JH10A | 287 | 35000 | m=20,z=12,x=+0.5 | 860 | 18.4 | 900~2200 | |

Our Advantages

QUALITY CONTROL SYSTEM

ISO 9001 is implemented strictly within all the manufacturing process. CHINAMFG products have all the necessary certificates and meet the relevant International Standards and Codes.

SPARE PARTS IN STOCK

We make sure that the spare parts CHINAMFG customers need are in stock in your country or can be delivered with Express post services. All the electrical components are purchased only from verified European suppliers.

EXTENDED WARRANTY

We pride ourselves in making high-quality products and offer an extended warranty for CHINAMFG cranes as a part of the Service agreement for maintenance and repair services.

CUSTOMISED PAINTING

Painting of your CHINAMFG tower crane can be tailored to suit your Company’s color and provide extra-protection for demanding weather conditions.

Company Profile

Established in 2003, CHINAMFG is a rapidly growing tower cranes manufacturer, whose reputation has been built on agile manufacturing, reliable service and competitive prices.

We are devoted to find the best solutions for our customers, improve production efficiency and reliability, save construction cost, introduce and apply the latest technologies in our products.

CHINAMFG provides the full series of high-quality construction machinery and overall solutions for construction sites. We have become a reliable partner in the field of design, cost estimation, manufacturing, sales, rental, maintenance, montage and after-sale services of the tower cranes for construction companies in more than 20 countries.

We are in an CHINAMFG of change, and change is opportunity. We must have strategic confidence and enhance our ability to adapt. We can’t cling to what has worked or what we have gained, because past success is not a reliable indicator of the future. In the end, a long list of accomplishments might end up nothing more than an epitaph. This is a vital fact that we must recognize. Moving forward, we need to hone our skills, step up to the plate, and aim for the stars. I would like to thank our customers and partners for your ongoing trust and support.

Let’s keep working closely, putting our best minds together to build a Better Connected World.

We give individual attention to every single detail to ensure that our clients are carefully looked after by professional management and well-trained staff. From conceptual plHangZhou through supply and on-going management, we tailor our package to meet the modern day demand.

OUR FACTORY

At ELMAK we’ve united an experienced team of designers and engineers to create and manufacture high-quality innovative products, that fully conform to the international standards.

We have a strict quality control and pay much attention to safety. All the raw materials are bought only from the trustworthy suppliers and carefully checked by the specialists.

MANUFACTURING PROCESS

-

3D design and analysis before production drawing;

-

ANSYS calculation;

-

Testing and verification of the calculation result;

-

Raw material inspection and manufacturing quality control strictly according to ISO9000 standard;

-

Robot welding machine and automatic cutting machine;

-

Painting line with first anti-corrosion layer and 2 surface layers after sandblasting;

-

Packing solution to make better protection and easy transportation

Packaging & Shipping

Our services

CHINAMFG Tower Cranes

ELMAK CRANE (ZheJiang ) CO., LTD

SALES

Elmak tower cranes come in hammerhead, flat top, and luffing jib varieties, offering different hook heights, jib lengths, and capacities to suit various construction needs.

If you’re unsure which crane to choose, simply share your requirements with us, and our team will help you select the most suitable tower crane for your construction site.

CHINAMFG Tower Crane Installation Services

ELMAK CRANE (ZheJiang ) CO., LTD

Installation/Dismantling Services

Our local CHINAMFG service team is dedicated to assisting and consulting during the erection and dismantling of tower cranes. Need additional support? An on-site service engineer can be appointed to supervise your project as part of our value-added service.

Our projects

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Video Technical Support, Online Support |

|---|---|

| Warranty: | 1 Year |

| Model: | Jh02 Jh07 Jh08 Jh13 Jh15 Jh17 Jh10A |

| Application: | Tower Crane |

| Product Name: | Slewing Reducer |

| Transport Package: | by Standrad Export Packing |

| Customization: |

Available

| Customized Request |

|---|

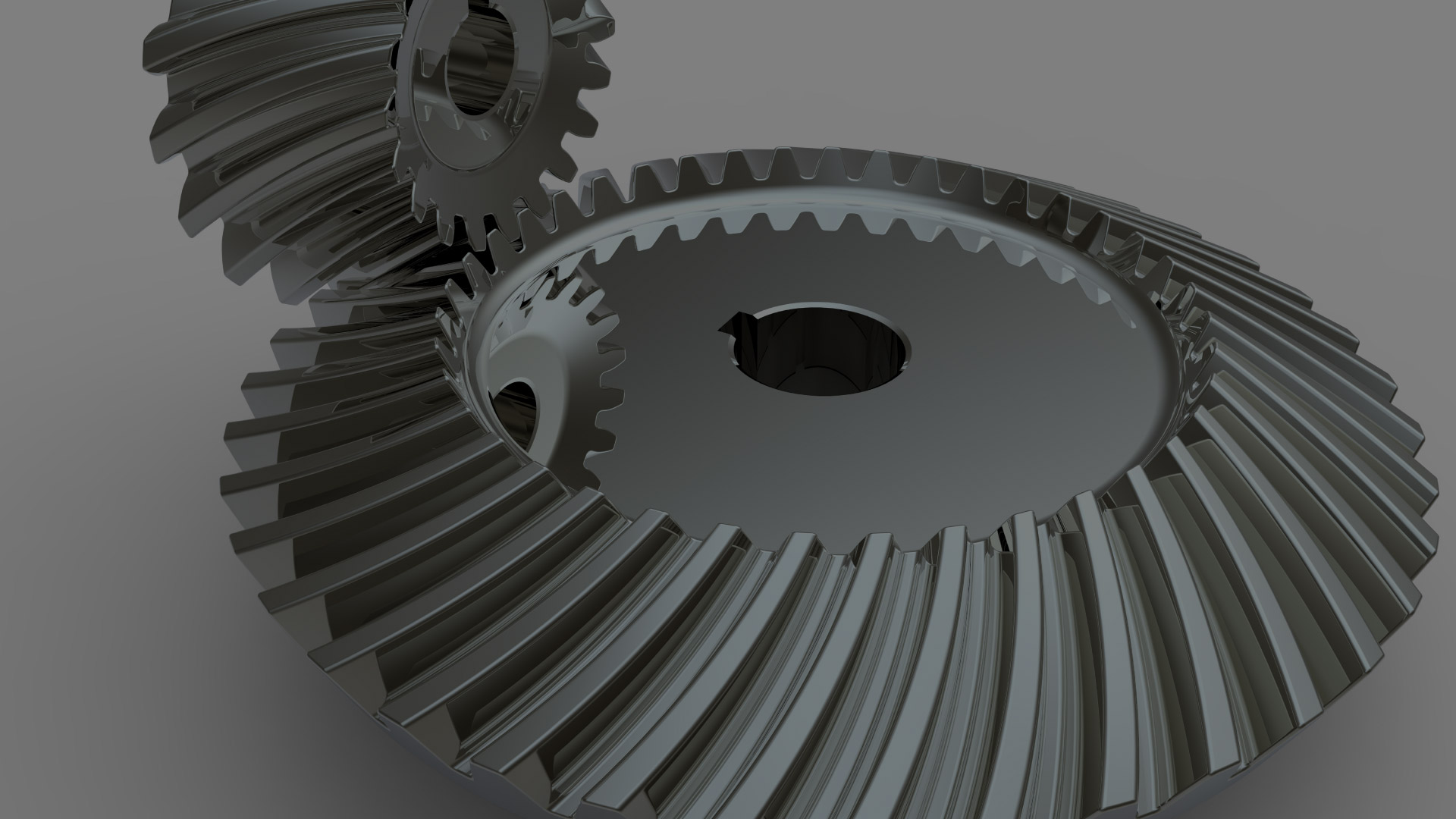

What are the advantages and disadvantages of using a bevel gear?

Bevel gears offer several advantages and disadvantages when used in mechanical systems. Understanding these pros and cons is crucial for selecting the appropriate gear type for a given application. Here’s a detailed explanation of the advantages and disadvantages of using a bevel gear:

Advantages of Bevel Gears:

- Power Transmission at Different Angles: Bevel gears are specifically designed to transmit power between intersecting shafts at different angles. They allow for efficient torque transmission and direction changes in applications where the input and output shafts are not parallel. This flexibility makes bevel gears suitable for a wide range of mechanical systems.

- Compact Design: Bevel gears have a compact and space-efficient design, allowing them to be used in applications with limited space constraints. Their ability to transmit power at an angle helps in optimizing the layout and arrangement of components in machinery and equipment.

- High Efficiency: Well-designed and properly maintained bevel gears can achieve high power transmission efficiency, typically above 95%. The efficient tooth engagement and load distribution in bevel gears minimize power losses due to friction and mechanical inefficiencies, resulting in energy-efficient operation.

- Smooth and Quiet Operation: Bevel gears generally provide smooth and quiet operation in properly designed and well-maintained systems. The meshing of the gear teeth is designed to minimize noise and vibration, ensuring smooth power transmission and reducing the need for additional noise-reducing measures.

- Versatility: Bevel gears are available in various configurations, including straight bevel, spiral bevel, and hypoid bevel gears. This versatility allows them to be used in a wide range of applications across different industries, accommodating different load capacities, speed requirements, and operating conditions.

- High Load Capacity: Bevel gears are capable of handling high loads and transmitting substantial amounts of torque. Their robust design, accurate tooth engagement, and strong materials make them suitable for heavy-duty applications where reliable power transmission is required.

Disadvantages of Bevel Gears:

- Complex Manufacturing: Bevel gears are more complex to manufacture compared to other gear types due to their three-dimensional shape and intricate tooth profiles. The manufacturing process involves specialized equipment and expertise, which can increase production costs.

- Cost: Bevel gears, especially those with high precision and load capacities, can be relatively expensive compared to other types of gears. The cost of materials, manufacturing complexity, and quality requirements contribute to their higher price.

- Potential for Noise and Vibration: In certain operating conditions, such as high speeds or misaligned gears, bevel gears can generate noise and vibration. This can be mitigated through proper design, accurate manufacturing, and maintenance practices, but additional measures may be necessary to reduce noise and vibration levels in some applications.

- Sensitive to Misalignment: Bevel gears are sensitive to misalignment, which can lead to increased friction, accelerated wear, and reduced efficiency. Proper alignment and control of backlash are essential for optimal performance and longevity of the gear system.

- Complex Lubrication: The lubrication of bevel gears can be more challenging compared to parallel-axis gears. Due to their angled tooth engagement, ensuring proper lubrication film thickness and distribution across the gear teeth requires careful consideration. Inadequate or improper lubrication can result in increased friction, wear, and reduced efficiency.

It’s important to consider these advantages and disadvantages of bevel gears in the context of specific applications and operating conditions. Proper design, selection, manufacturing, and maintenance practices can help maximize the benefits of bevel gears while mitigating their limitations.

What are the environmental considerations when using bevel gears?

When using bevel gears, there are several environmental considerations to keep in mind. These considerations encompass aspects such as material selection, lubrication, noise generation, and waste management. Here’s a detailed explanation:

1. Material Selection: The choice of materials for bevel gears can have environmental implications. Opting for environmentally friendly materials, such as recyclable or biodegradable materials, can help reduce the environmental impact. Additionally, selecting materials with low toxicity or hazardous properties contributes to safer handling and disposal practices.

2. Lubrication: Proper lubrication is essential for the efficient operation of bevel gears. However, the choice and use of lubricants can have environmental consequences. It is advisable to select lubricants that are environmentally friendly, such as biodegradable or non-toxic lubricants, to minimize the risk of contamination in case of leaks or spills. Additionally, implementing effective lubricant management practices, such as proper containment and recycling, helps reduce environmental pollution.

3. Noise Generation: Bevel gears can generate noise during operation, which can have environmental implications, especially in noise-sensitive areas or workplaces. Excessive noise can contribute to noise pollution and affect the well-being of individuals in the vicinity. Implementing noise reduction measures, such as using noise-dampening materials, optimizing gear design for quieter operation, and implementing proper maintenance practices, can help minimize noise pollution.

4. Energy Efficiency: Bevel gears are part of power transmission systems that consume energy. Considering energy efficiency in gear system design and operation can contribute to reduced energy consumption and lower environmental impact. This can be achieved by optimizing gear designs for higher efficiency, reducing friction losses through proper lubrication and surface treatments, and implementing efficient power transmission systems.

5. Waste Management: The manufacturing and maintenance processes involving bevel gears can generate waste materials, such as metal shavings, lubricant residues, or worn-out gears. Proper waste management practices, including recycling and disposal, are crucial to minimize the environmental impact. Recycling materials whenever possible and ensuring the proper disposal of hazardous or toxic waste materials are important considerations in reducing environmental pollution.

6. Life Cycle Assessment: Conducting a life cycle assessment (LCA) of bevel gears can provide a comprehensive understanding of their environmental impact. LCA takes into account the environmental implications associated with the entire life cycle of the gears, including raw material extraction, manufacturing, use, and end-of-life disposal. This assessment helps identify areas for improvement and guides decision-making towards more sustainable practices.

By considering these environmental factors, manufacturers, engineers, and users of bevel gears can make conscious choices to minimize the environmental impact associated with their production, operation, and disposal. Implementing sustainable practices and adhering to environmental regulations and standards contribute to a greener and more sustainable use of bevel gears.

What are the applications of a bevel gear?

A bevel gear finds applications in various industries and mechanical systems where changes in direction or speed of rotational motion are required. Here’s a detailed explanation of the applications of a bevel gear:

- Automotive Industry: Bevel gears are widely used in the automotive industry, particularly in differentials. Differentials are responsible for distributing torque between the driving wheels of a vehicle, allowing them to rotate at different speeds when turning. Bevel gears in differentials transmit power from the engine to the wheels, enabling smooth cornering and improved traction.

- Mechanical Power Transmission: Bevel gears are employed in mechanical power transmission systems to change the direction of rotational motion. They are used in applications such as power tools, machine tools, conveyors, and printing presses. By meshing with other bevel gears or with spur gears, they transmit torque and power efficiently from one shaft to another, accommodating changes in direction and speed.

- Marine Propulsion Systems: Bevel gears are extensively used in marine propulsion systems, including boats and ships. They are commonly found in the propulsion shaft line, where they transmit torque from the engine to the propeller shaft, allowing the vessel to move through water. Bevel gears in marine applications are designed to withstand high loads, resist corrosion, and operate efficiently in harsh environments.

- Aerospace Industry: Bevel gears are utilized in various aerospace applications. They are employed in aircraft landing gear systems, where they transmit torque from the hydraulic motor to extend or retract the landing gear. Bevel gears are also found in helicopter rotor systems, providing the necessary power transmission to rotate the rotor blades.

- Railway Systems: Bevel gears play a crucial role in railway systems, particularly in locomotives and rolling stock. They are used in the transmission systems to transfer power from the engine to the wheels. Bevel gears ensure smooth and efficient power transfer, enabling the train to move forward or backward while negotiating curves on the track.

- Industrial Machinery: Bevel gears are extensively employed in various industrial machinery, such as milling machines, lathes, and industrial robots. They facilitate changes in direction and speed of rotational motion, enabling precise positioning, accurate cutting, and smooth operation of the machinery.

- Mining and Construction Equipment: Bevel gears are used in mining and construction equipment to transfer power and torque in heavy-duty applications. They are found in equipment such as excavators, bulldozers, and crushers, where they provide reliable power transmission in challenging environments.

These are just a few examples of the applications of bevel gears. Their ability to transmit power, change the direction of rotational motion, and accommodate intersecting shafts makes them versatile and suitable for a wide range of industries and mechanical systems.

In summary, bevel gears are extensively utilized in automotive differentials, mechanical power transmission systems, marine propulsion systems, aerospace applications, railway systems, industrial machinery, and mining and construction equipment. Their applications span across industries where changes in direction or speed of rotational motion are essential for efficient and reliable operation.

editor by CX 2024-04-17